Custom Patch Hat Guide

Posted by Emily Ayers on Nov 9th 2022

Artwork: Before & After

See how accurate your artwork will look when it becomes a patch! We want to make sure you are confident in the custom patch hats you will receive. We heat seal all of our patches in house on each hat at over 300 degrees so the patch will not come off of the hat. Keep in mind, even if the edges/border are loose, the patch itself is super sealed to the hat so it will not come off.

Woven Patch Examples

When it comes to popularity, a woven patch is the most requested! You can capture finite detail and small text that will result in a clean, crisp and vibrant logo. A woven patch uses intricately woven materials (hence the name) to capture more of the finer details of your personalized logo. The woven patch is a great choice if your logo has fine details or smaller text or numbers.

1.8"H x 3.2"W

2.5"H x 1.68"W

Embroidered Patch Examples

Embroidered patch hats are the closest to “regular” embroidered hats and are the most common type of patch. The embroidered patch adds a contrasting border edge to really make your logo stand out. With embroidered patches, you can use either a twill or fully embroidered background. You can typically capture more details on a patch than you can with regular embroidery, but some smaller, more intricate details may not show well on this option.

2.5"H x 2.91"W

2"H x 3.66"W

Leather Patch Examples

Leather patches lend themselves to a more basic + simple logo, although smaller details can be achieved. For the leather patch, there are two choices of materials: genuine or faux leather. From there, there is a variety of base colors to choose from. These leather patches are a little different because we will etch your logo onto the leather material and then apply that to the cap. With that being said, for this type of leather patch to work for you, your logo will need to be able to be converted into a single-color version. If it is not already, we can help you create that.

2.25"H x 4"W

2.5" Diameter

Sublimated Patch Examples

Sublimated patch hats are the choice for you if your logo has intricate, small details or gradient colors. This type of patch is similar to the screen-printing process, so we are able to replicate almost any detail and color on the patch. *Colors tend to be more matte and do not have as much contrast. Black, for example, does not show up as true black. If you have mostly neutral colors, we recommend any of the other patch options shown above. Sublimated patches are the way to go if you have detail or gradients in your logo.

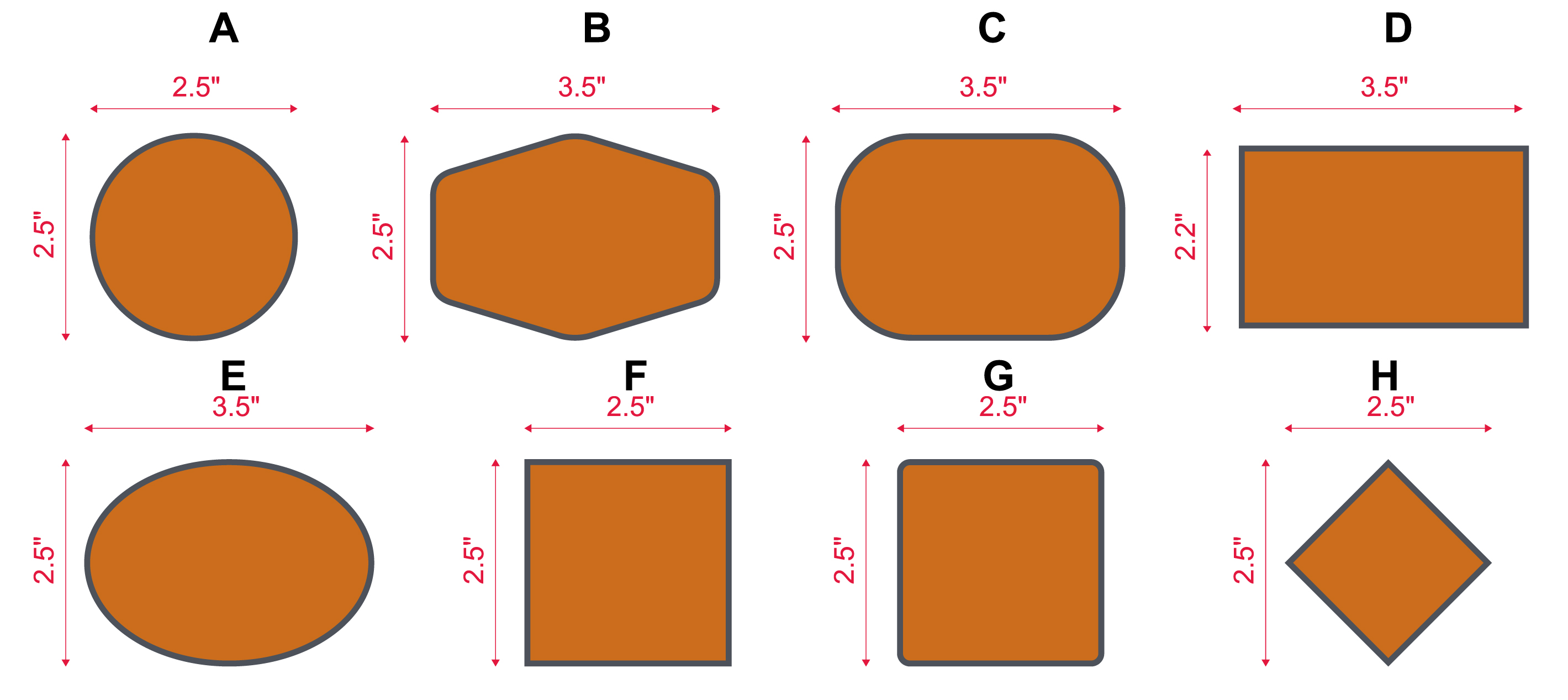

Patch Sizes & Shapes

We can create any patch shape desired! The most common is to use simple shapes - square, rectangle, oval, circle, etc - these shapes work best for a merrowed edge border (which is what most people want) - and we can size the shape however is needed to best fit the logo. We use rectangles a lot, but often it's dictated by the shape/layout of the customer's logo and what will make it look best. Often, customers have some specific ideas as well and we can almost always accommodate. We can create detailed patch shapes as well - usually on these we have to do an embroidered edge as too much detail in shape won't work for merrowed edge.

We can go up to 2.4" tall for patches. It's larger than what we can do with direct embroidery. "Standard width" is still 4" wide like normal decoration but we can go wider up to 5" if needed. 4" W x 2.25" H is kind of the "sweet spot" we live in - but we usually recommend sizing based on what we think your logo needs (a more vertical oriented logo, a circle, etc - often will go right to the max 2.4" height. Most people generally like a little larger patch, but sometimes people want something a little smaller, which we can do no problem, just something to identify in the ordering process.

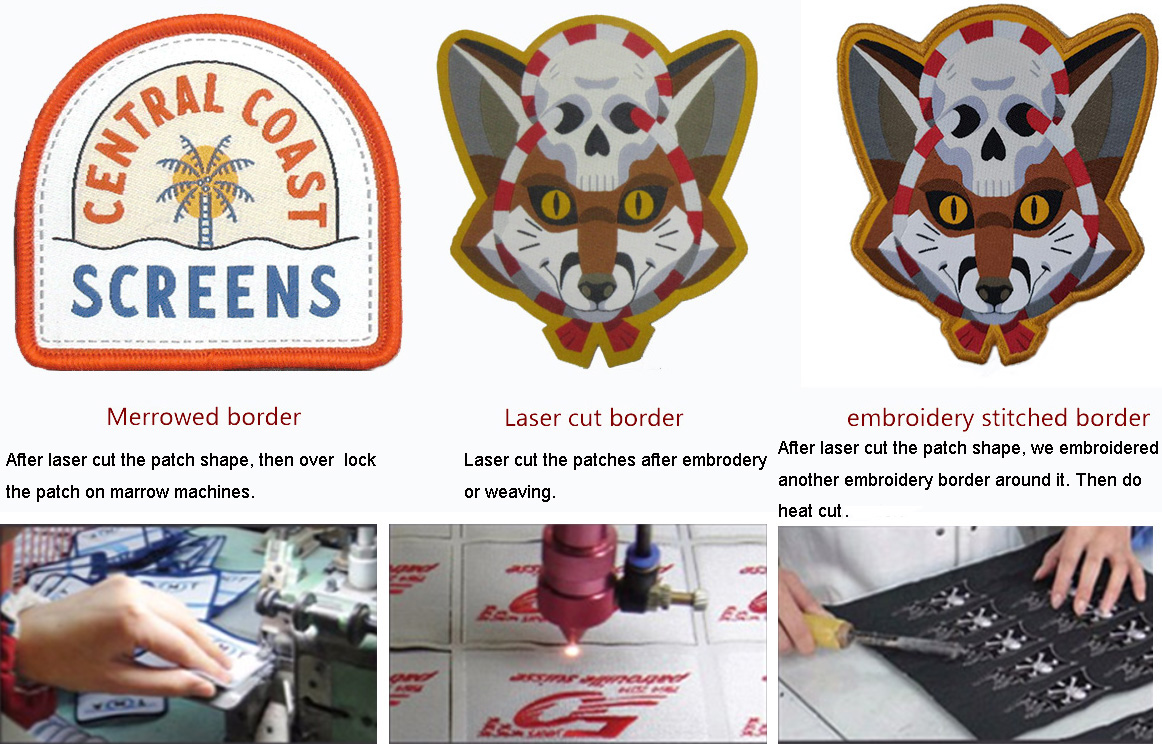

Patch Edges

MERROWED EDGE

This patch edge is the most common - we use it for about 90% of custom patches. The stitching is tight and makes the patch looked more raised. The glue may not go all the way to the edge, so the border may appear like it's slightly coming off. The way we press the patch on the hat does not allow the patch to come off.

Any simple shaped patch can have a merrowed edge border.

This option has a HUGE color selection - it can be chosen to tie in with your logo or the color of the hat, or it can align with background color of patch for a more subtle look.

EMBROIDERED STITCHED EDGE

Similar to merrow but a lower profile/height - gives patch a flatter look without the raised edge.

Better (or sometimes required) for more complex shaped patches that are not suited to merrowed edges.

Same variety of color selections as merrowed edges.

LASER CUT EDGE

No separate stitched edge - simply a clean cut on the fabric of the patch.

This style is the least used. According to our brand experts they don't look great.

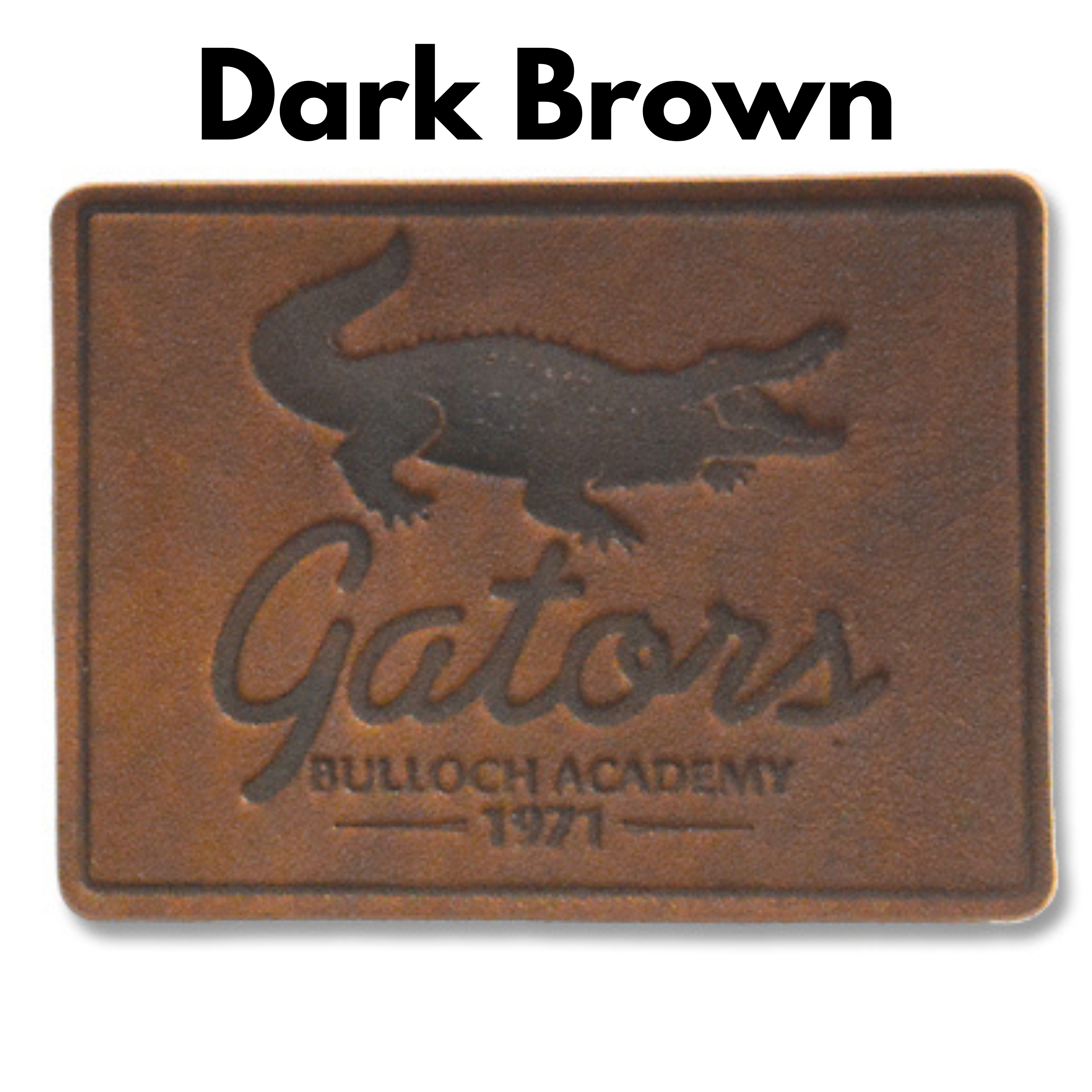

Leather Patches

Welcome to the custom leather patch section! They can be a little different, so let's go over why that is.

Everything about size/shape above applies to leather patches.

There is no outer border options with leather patches, so that makes the process one step simpler. There is a pretty wide spectrum of leather colors we can do, however we generally only give the option of Light / Medium / Dark Brown leather patch options.

We can do faux leather patches in various colors but again, this is something we don't do often. Most of the time customers are just wanting the standard brown leather patches.

One option we often present is the "border outline." This is not standard, we have to make sure to include it on design (It's called a "stitching channel" - if you're sewing down patches, this is where you sew the track that holds the patch to hat. Since we just heat seal, we don't need to include this, but it's visually appealing. so a lot of times we recommend it to customers.

There actually is an option for to include a stitch look on the edge of the patch - so even if we are not sewing the patch down, you get that stitched edge look. They call this "real stitching."